The PCO 1881 cap, also known as the 28mm neck carbonated beverage cap, differs from ordinary water bottle caps in that they face a unique challenge: sustained internal pressure. This internal pressure ensures the beverage's smooth, refreshing taste and a full, aerated texture, but it also presents a design challenge. Therefore, it has clear design objectives:

1. Maintain a tight seal: Absolutely prevent carbon dioxide leakage, ensuring the product remains fully aerated throughout its shelf life.

2. Safe opening: Provide a controlled pressure release to prevent sudden release and splashing.

3. Withstand pressure: The cap and finish system must withstand internal pressure for extended periods without deformation or failure.

| Core Applications | Suitable for carbonated beverages such as cola, soda, and other carbonated beverages; also suitable for juice and mineral water (depending on actual needs). |

||||

| Sealing Requirements | Extremely high. Requires long-term resistance to internal carbon dioxide pressure. | ||||

| Special Design | Safe "degassing before disconnecting": Initially releases some gas upon opening to prevent bottle explosion and splashing. | ||||

How it work

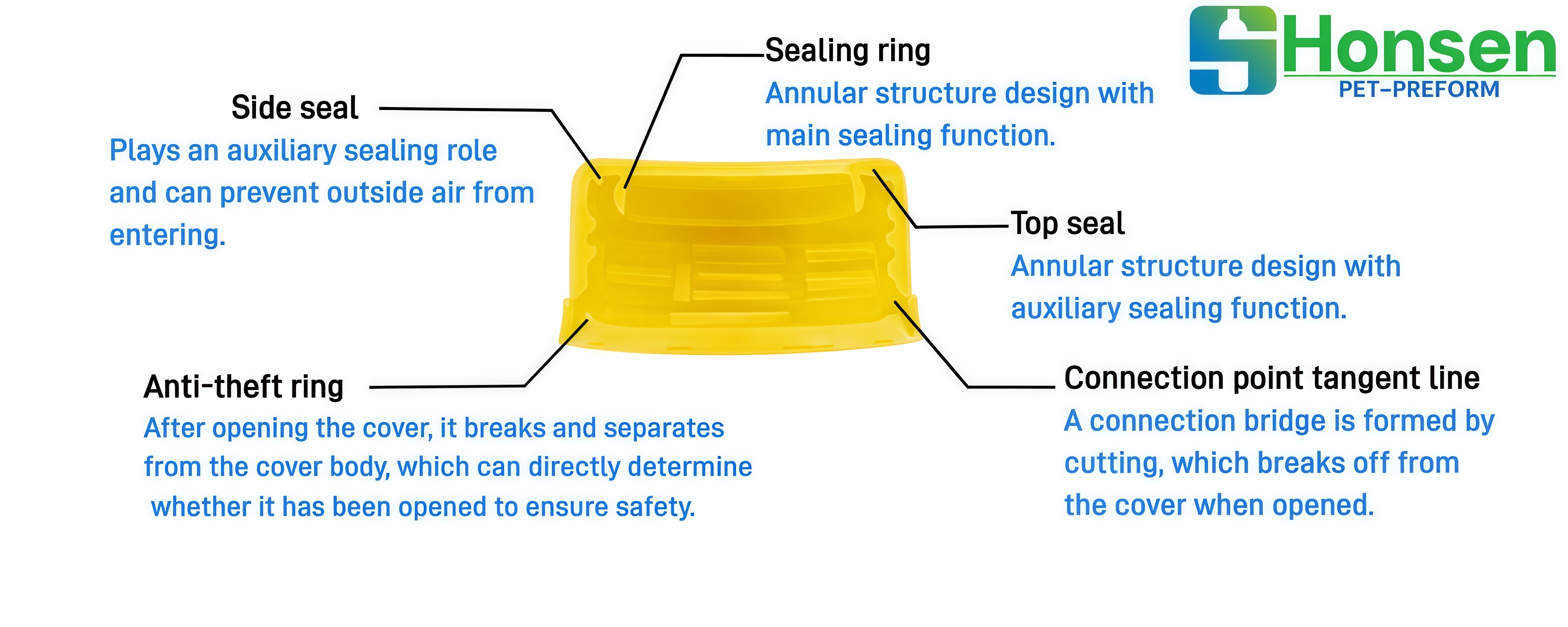

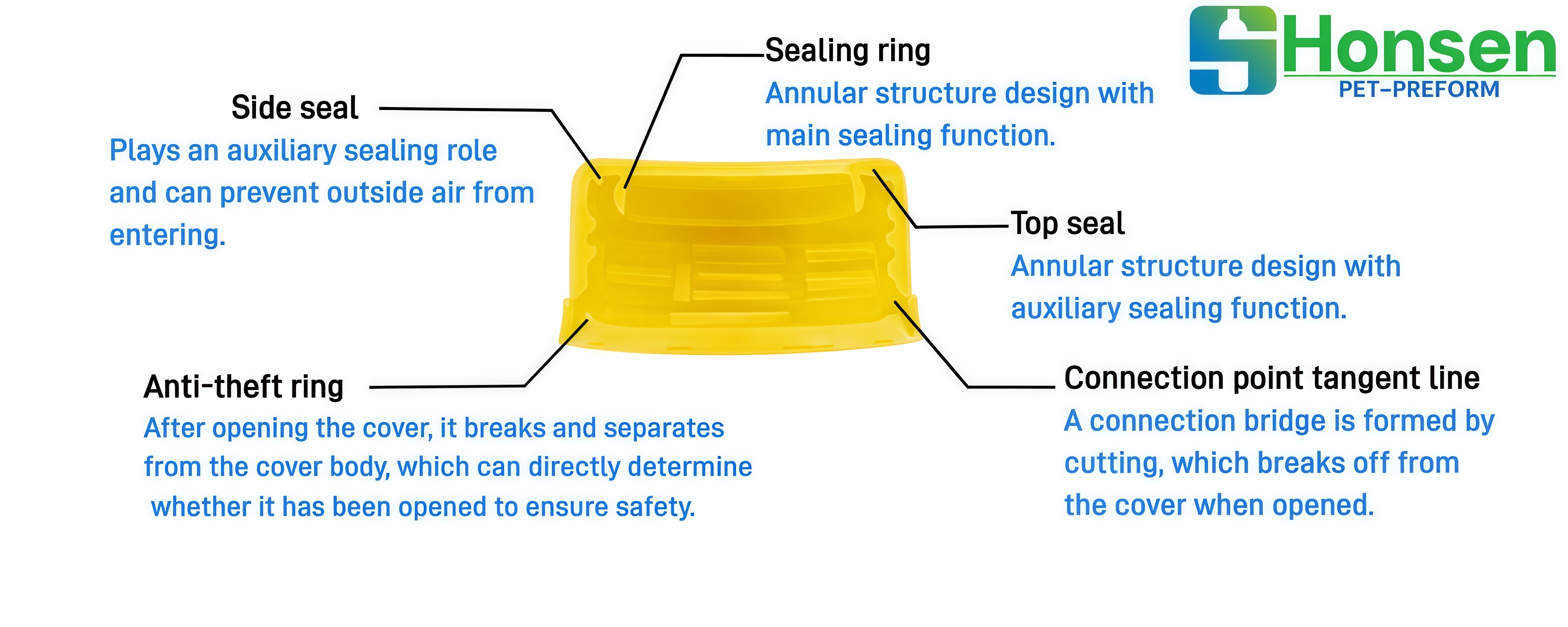

1.When a new cap is screwed onto a bottle, presses the ring downward, forcing it to slide over a raised locking bead below the bottle's threads.

2. Once it slides over, the barbs inside the anti-tamper ring are trapped by the locking bead, preventing further upward movement.

3. When you first unscrew the cap, the main sidewall moves upward, but the trapped anti-tamper ring prevents it from following.

4. This upward force instantly breaks the delicate "bridges" connecting the cap and the anti-tamper ring, completely separating the cap and the ring, confirming that the bottle has been opened for the first time.

Foshan Honsen Plastic Industry Co., Ltd. is a professional preform manufacturer with a reliable business scope. The company's main business scope is the production and development of PET preforms, PET plastic bottles, and packaging for drinking water and beverage products. We are Manufacturers and Custom Factory. Honsen is committed to technological innovation and product quality improvement, providing customers with innovative and environmentally sustainable packaging solutions. We use advanced production equipment and processes to ensure reliable product quality. Whether it is from raw material procurement to production process control, we take it seriously to follow industry regulations to ensure product safety and environmental performance. Whether you need a large number of standardized preforms or special customized products, we can meet your needs. If you are looking for a high-quality, safe and harmless food-grade plastic container, please feel free to contact our sales manager for more information.