The Unseen Foundation: A Deep Dive into the Materials Used in Plastic Bottle Preforms

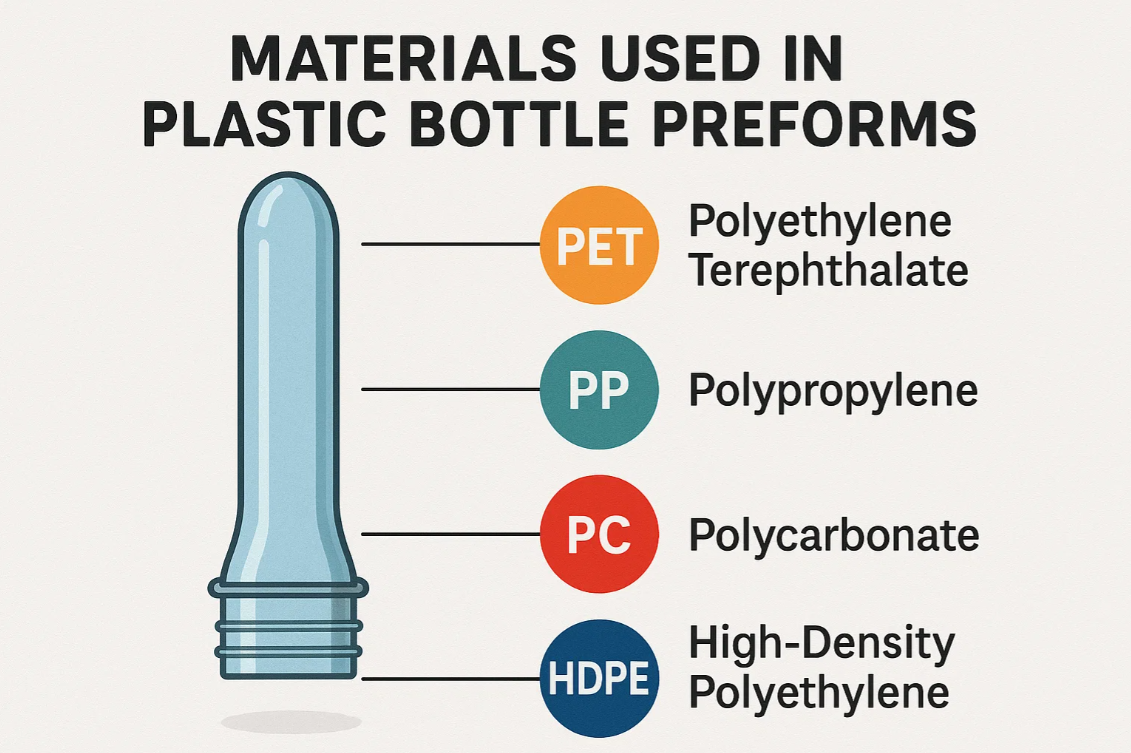

Before a plastic bottle takes its familiar shape on the supermarket shelf, it begins its life as a much smaller, test-tube-like object: a preform. These humble-looking precursors are the critical foundation of the modern beverage and liquid product industry. The choice of plastic for these preforms is a carefully considered decision, balancing factors like clarity, weight, cost, and the specific needs of the product it will eventually hold. While Polyethylene Terephthalate (PET) is the undisputed champion in this arena, other plastics like High-Density Polyethylene (HDPE) and Polypropylene (PP) play crucial roles in specific applications. This article explores the science behind these materials and their significance in the world of plastic bottle preforms.

The Reign of PET: Clarity, Strength, and Recyclability

Polyethylene Terephthalate, or PET, is the most common material used for plastic bottle preforms, especially for beverages like water, carbonated soft drinks, and juices. Its widespread adoption is due to a unique combination of desirable properties that make it an almost perfect material for this purpose.

One of the most apparent advantages of PET is its exceptional clarity and transparency. This glass-like quality allows consumers to see the product, enhancing its appeal on the retail shelf. Beyond aesthetics, PET is lightweight yet remarkably strong and shatter-resistant, offering a significant advantage over glass in terms of safety and transportation costs.

From a product preservation standpoint, PET possesses excellent barrier properties against oxygen and carbon dioxide. This is crucial for maintaining the fizziness of carbonated drinks and preventing the oxidation that can alter the taste and quality of beverages. Furthermore, PET is a non-toxic material that does not leach harmful substances into the contents, ensuring the safety of food and beverage products.

In an era of increasing environmental awareness, the high recyclability of PET is a key factor in its popularity. Used PET bottles can be collected and reprocessed into recycled PET (rPET), which can then be used to create new bottles and other products, promoting a circular economy.

The journey from resin to preform for PET involves a process called injection molding. PET pellets are dried to remove moisture, melted, and then injected under high pressure into a mold to form the preform. This process is highly efficient, allowing for the mass production of consistent and high-quality preforms.

HDPE: The Robust Choice for Rigidity and Chemical Resistance

High-Density Polyethylene (HDPE) is another major player in the world of plastic bottles, though it serves different applications than PET. Unlike the crystal-clear appearance of PET, HDPE is naturally translucent or opaque. This makes it unsuitable for products where clarity is paramount, but it excels in other areas.

The primary strengths of HDPE are its exceptional durability, impact resistance, and chemical resistance. This makes it the ideal choice for packaging products like milk, detergents, shampoos, household cleaning agents, and motor oil. HDPE bottles can withstand rough handling and are less likely to be compromised by corrosive chemicals.

HDPE is also a food-safe and BPA-free plastic, making it a reliable choice for packaging dairy products and other foodstuffs. While not as transparent as PET, HDPE can be colored to create a wide range of vibrant and opaque packaging options. Like PET, HDPE is also widely recycled. The injection molding process for HDPE preforms is similar in principle to that of PET, though processing temperatures and other parameters are adjusted to suit the specific properties of the material.

PP: The Champion of Hot-Fill and Hinge-Top Applications

Polypropylene (PP) is a versatile thermoplastic that finds its niche in the preform market, particularly for applications requiring higher heat resistance. This makes PP the go-to material for “hot-fill” bottles, which are filled with products at high temperatures to sterilize them, such as certain juices and sauces.

In addition to its heat tolerance, PP offers good chemical resistance and a strong barrier against moisture. It is also a lightweight and durable material. While typically less transparent than PET, clearer grades of PP are available. A common application for PP in the bottle industry is for caps and closures, including those with integrated hinges, due to its excellent fatigue resistance. PP is also a recyclable material.

The Rise of rPET: A Sustainable Imperative

As the demand for sustainable packaging solutions grows, the use of recycled PET (rPET) in bottle preforms is becoming increasingly prevalent. rPET is produced from post-consumer PET bottles that are collected, sorted, cleaned, and reprocessed into pellets. These pellets can then be used to manufacture new preforms, often blended with virgin PET.

The use of rPET offers significant environmental benefits, including a reduction in plastic waste ending up in landfills and oceans, lower carbon emissions compared to the production of virgin PET, and the conservation of natural resources. While there can be challenges in maintaining the same level of clarity and performance as virgin PET, advancements in recycling technology are continually improving the quality of rPET.

Other Plastics Making Their Mark

While PET, HDPE, and PP dominate the landscape, other plastics are used for specific, often high-end, applications:

- PETG (Polyethylene Terephthalate Glycol-modified): This material offers excellent clarity, toughness, and chemical resistance, making it a popular choice for cosmetic and personal care product containers. Its enhanced impact resistance compared to standard PET makes it a durable option for premium packaging.

- PMMA (Polymethyl Methacrylate): Commonly known as acrylic, PMMA is used to create preforms for luxury cosmetic packaging that mimics the appearance of glass. It boasts high transparency and can be easily colored and decorated.

The Role of Additives and Colorants

To enhance the performance and appearance of plastic bottle preforms, various additives and colorants are often incorporated during the manufacturing process. These are typically mixed with the raw plastic pellets before injection molding. Common additives include:

- UV Blockers: To protect the contents of the bottle from degradation by ultraviolet light.

- Gas Barrier Additives: To further improve the barrier properties against gases like oxygen and carbon dioxide, extending the shelf life of the product.

- Colorants: To produce bottles in a wide spectrum of colors, which can be important for branding and product differentiation.

- Processing Aids: To improve the efficiency of the injection molding and blow molding processes.

Conclusion

The simple plastic bottle preform is a testament to the advanced materials science that underpins our modern world. The dominance of PET in the beverage industry is a result of its unparalleled combination of clarity, strength, and recyclability. However, the diverse needs of the packaging industry have carved out important roles for other plastics like the robust and chemical-resistant HDPE and the heat-tolerant PP. As sustainability continues to drive innovation, the increasing use of rPET and the exploration of other high-performance plastics will ensure that the humble preform continues to evolve, shaping the future of packaging in ways that are both functional and environmentally responsible.

English

English